Why use Roof Trusses? So glad you asked.

As building inspections and building codes become more stringent and engineer reliant, more and more builders choose roof trusses over stick framing. The advantages are clear:

- Each component is engineered for its specific location

- Design liability is placed where it belongs: on a structural engineer

- Less time spent in framing

- Less time with the floor and walls exposed to the weather

- Complex roof lines are much easier to build with trusses

Clear Spans

It goes without saying that trusses allow for larger clear spans than stick framing.

We take pride in building the highest quality trusses in the business. From design to installation, we will be available to answer any questions you may have.

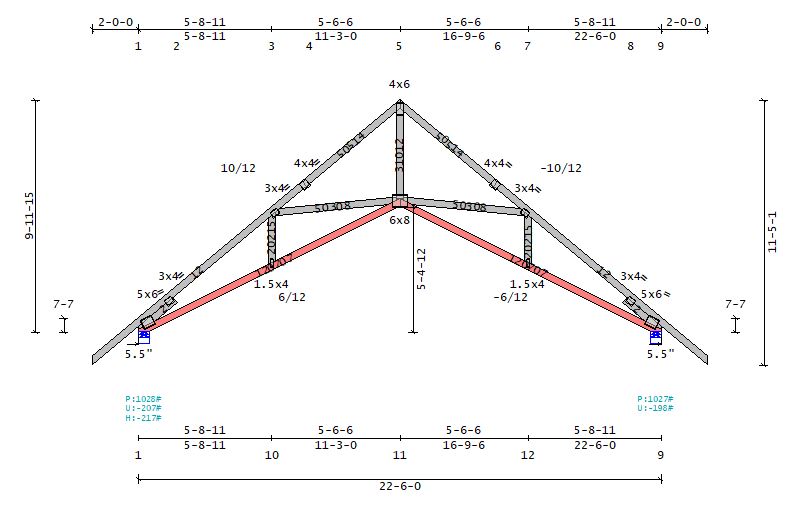

Scissor Trusses can add a luxurious and spacious feeling to any room. Normally, a scissor truss can be engineered with half as much slope on the bottom chord as the top chord. Of course that’s not a given. Low pitch roofs, such as 4/12 or less, may not allow for half the slope of the top chord. Conversely, steeper roofs may allow for more than half the top chord pitch, as in the truss shown above, where the top chord pitch is 10/12 and the bottom chord pitch is 6/12.

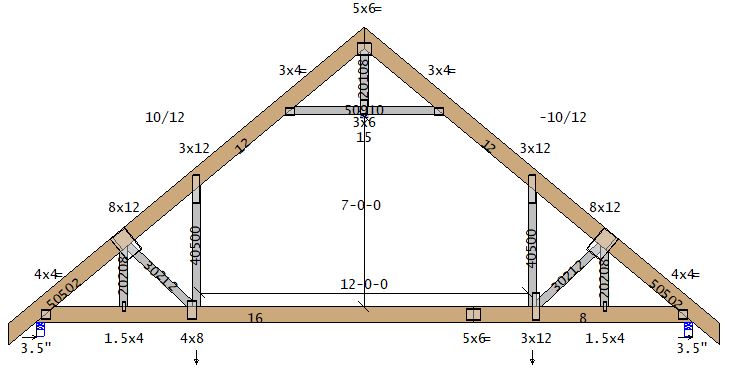

Room – in -Attic Truss

Attic trusses are a relatively cheap way to add either storage or living space.

Attic trusses that will be used as living area must be designed to a higher per square foot load, usually 40 psf live load, and may fall under local code requirements for room height. It’s important to know what those local requirements are when requesting a truss quote, so that we can maximize the available space in the truss.

Storage attic trusses are typically designed to carry 25 psf live load. While trusses in a garage may not be tall enough to create a full size room, many of our customers have utilized that extra space by going with attic trusses. The one time cost of upgraded trusses may be well worth it in the long run.

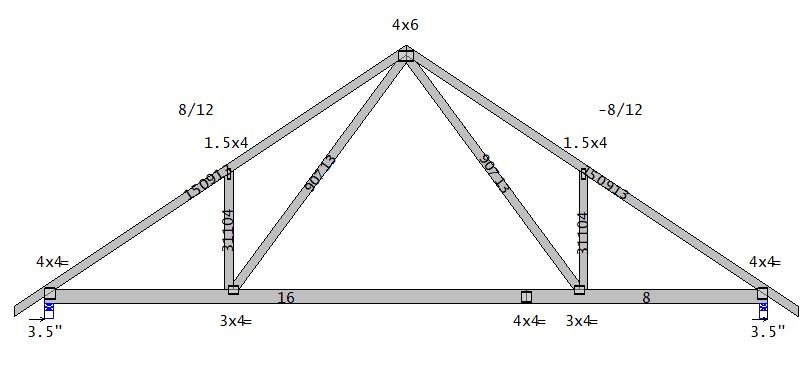

Spread-Web Design

An option to add storage area without the full cost of an attic room is to use a Spread Web design. While this is not quite as clean and open as an attic truss, it can be a very economical way to add storage space. And there’s no need to worry that the truss will not be loaded for the storage area. Simpson Strong-Tie’s engineering software automatically adds storage loads Spread-Web locations.

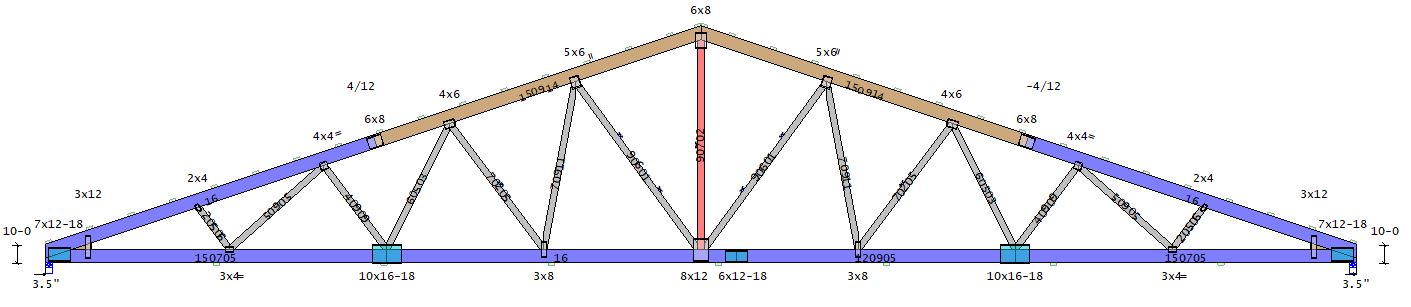

Ag Trusses

Ag trusses are typically used for agricultural buildings such as hay sheds, machine sheds, or livestock shelter. While there are as many variations in ag trusses as in other trusses, ag trusses have one thing in common; they are always spaced further than 24″ O.C., and they take reductions in loads because they are not intended for human occupancy.

Roof Truss Loading

Our roof trusses are currently designed under the following criteria:

• Building Code: IRC 2018/TP 1-2014

• Load Provisions: ASCE7-16

• Roof Truss Standard Loads: TC Live – 30 psf; TC Dead – 10 psf; BC Live – 0 psf; BC Dead – 10 psf

• Ground Snow Load: 30 psf

• Deflection: L/360

While we do our best to ensure that the trusses we design meet all the design requirements of the job-site location, it is ultimately the customer’s responsibility to verify that all local codes and requirements are met. We will of course change the designed code or loading to meet any specific requirement upon request.

To read more about what all the loading numbers mean, click here for our FAQ page

Lateral Bracing

Lateral bracing on a truss web is noted on the sealed drawings, and marked on the truss web itself.

There are multiple methods of bracing webs, depending on whether or not they lines up with other webs. The Structural Building Components Association has bracing guidelines, and you can see them on their site.

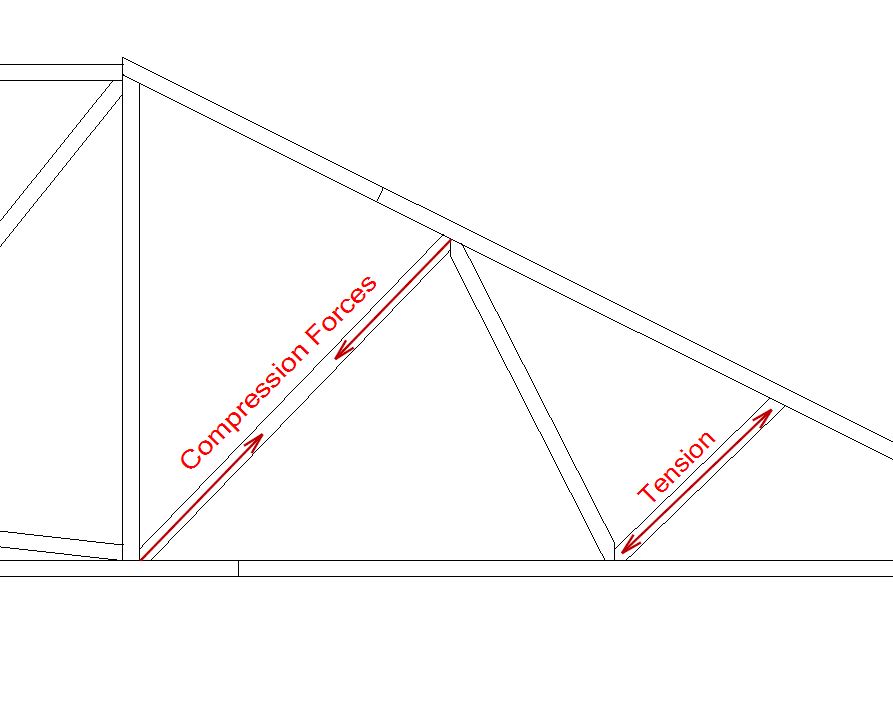

Why does the web needs a brace? To understand that, we need to understand the two opposite forces that act on the webs in our trusses: Compression, and Tension.

In the example below, the left web is more likely to require a brace.

Our engineering software calculates all the forces in each truss member. When compression forces on a web are too great, it could bow out and potentially break under full load. In that case, the software notes that a brace is required. Sometimes we can up the grade on the web material to avoid our customers having to add lateral braces in the field, but we can’t avoid all lateral braces.

Color Coding

You might notice when you get a set of roof trusses from us, that they have different colors of paint at the splices, like the photo below.

So why do we do that?

First off, let’s think a little bit about lumber grades. Not every 2X4 is created equal. We stock a minimum of three grades of 2X4. For example, #2, MSR1650, and MSR2100. “#2” is a visual grade, while MSR stands for “Machine Strength Rated”. When we design trusses, our software chooses from our available lumber grades to use the most cost effective lumber that will still meet the strength requirement for each truss component.

When we cut out a job, we batch the pieces for the entire job into one large cut list. Let’s say there are 50 boards that are identical, except for grade. The sawyer cuts 50 boards from a variety of different grades. When he’s done, they look exactly the same on the lumber cart, except for the tiny grade stamp that may or may not show because it is only on one side of the board. This is dangerous, because it makes it too easy for the guys on the assembly line to throw in the wrong grade board on a truss. That’s why we devised our color coding system.

Does this system take a little more time and effort? Of course it does. But it’s just one example of an extra step we take to ensure that the trusses you get will be built correctly. We think it’s worth it.